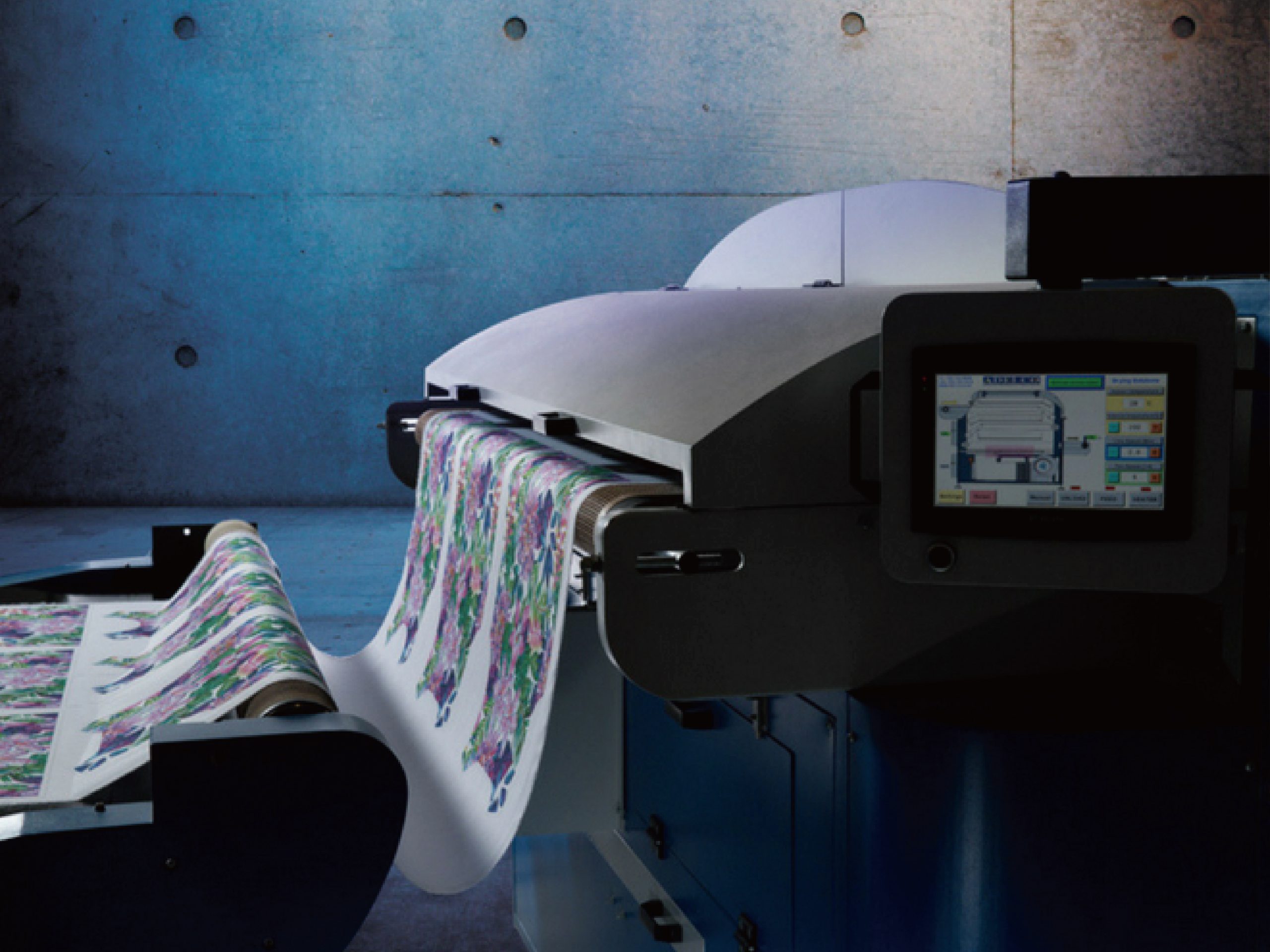

Digital Textile Printing is “a process of printing on textiles and garments using inkjet technology to print colorants onto fabrics”. It allows for a single piece, mid-to small-run cycle production and even long-run as an alternative option to screen printed fabric (Chen, 2018). Digital textile printing is used to help printers to meet demands for high-quality designs, short-runs, and rapid turnarounds, which it will help customers to bring new ideas to the market faster.

Source: Chen, N., 2018. What is Digital Textile Printing | Kornit Glossary. [online] Kornit Blog. Available at: https://www.kornit.com/blog/glossary-item/digital-textile-printing/

It has been a printing production method for decades, and it started out for proofing and design purposes with a small niche market for one-off fashion fabrics and garments. The dye sublimation via inkjet was launched in 1990s and the first roll-to-roll digital direct textile printer was in operation in the end of the decade (WALSH, 2021).

Source: WALSH, S., 2021. The Future Of Digital Textile Printing To 2026 | Market Reports & Research | Smithers. [online] Smithers. Available at: https://www.smithers.com/services/market-reports/printing/the-future-of-digital-textile-printing-to-2026#:~:text=Digital%20textile%20printing%20has%20been%20a%20print%20production,roll-to-roll%20digital%20direct%20textile%20printer%20was%20in%20operation.

Digital Textile Printing has been operated through transferring media, such as screens and rollers, and each transferring media is designed and allocated for a specific color. Advantages such as having three dimensional effects due to its color separation and layers. Also, it achieved with greater flexibility without the limitation of on repeat sizes, colors, engineered designs and gets outstanding depiction of continuous tone images (Jahic, 2019). Moreover, digital textile printing method is using less waste as droplets of ink are being printed very precisely onto the fabric with no disposal of excess dye and chemicals used in rotary screen printing, harming the environment. It involves very low power and water consumption as compared to conventional printing. It uses less ink and minimizes waste. Which digital textile printing offers much more environmentally friendly process. Source: Jahic, D., 2019. What is digital textile printing and what are the advantages for your company?. [online] Blog.spgprints.com. Available at: https://blog.spgprints.com/what-is-digital-textile-printing